|

+ (800)-424-5353 |

|

or Email |

|

|

|

|

| ABOUT US |

|

RAILROAD POCKET WATCHES

| THAT GREAT AMERICAN RAILROAD POCKET

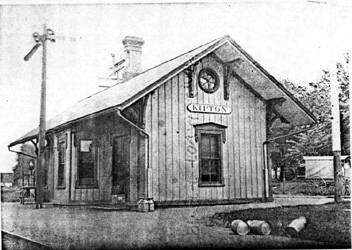

WATCH It was the late nineteenth century in America. The automobile had not yet been discovered. The personal Kodak camera was still not on the market. Women wore long dresses, and the rub board was still the most common way to wash clothes. Few homes had electricity, and certainly the radio had not yet invaded their lives. Benjamin Harrison was president. To be sure, those days of yesteryear were not quite as nostaligically simple as most reminiscing would have them be. They were slower, yes, because it took longer to get things done and longer to get from one place to another. The U.S. mail was the chief form of communication linking this country together, as America was inching toward the Twentieth Century. Truly the train station held memories for most everyone and had a link with every family. Taking effect June 15, 1892, the Illinois Central Railroad inaugurated a watch inspection. Employees are now required to summit their watches for a quarterly examination and weekly comparison with standard time to the various local inspectors who have been appointed for the purpose. The minimum standard of watches is of a grade equal to what is known among American movements as 15 jewels, patent regulator, adjusted to temperature, the variation of which must not exceed e30 seconds per week. The Great American Railroad Pocket Watch, unrivaled in quality and reliability. "What is a railroad watch"? There is not an easy answer to this question. With 500 to 1,000 American Railroads and each one used many different rules and specifications. Some railroads used requirements only and some listed only watch company grades that were acceptable Also Railroad rules and watches evolved and changed from year to year. In the late 1860s a movement was commissioned by Pennsylvania Railroad Co. and had "Pennsylvania Railroad Co." on the dial and "B.W. Raymond" on the movement. The movement made by Elgin was a 18 size, 15 jewels, key wind and set. In 1887 the American Railroad Companies had a meeting to interpret and specify requirements of standard time and watch inspection. In the spring of 1894, a American Waltham Watch Co. ad states "Systematic railroad watch inspection was first adopted during recent years" The ad also says "Waltham watch movements expressly designed for railroad use". The ad shows a 1892 model Vanguard grade with 17 jewels and a double roller. In Feb. 02 1894, The United States Watch Co. of Waltham introduced a first quality nickel, 18 size, full plate, stem winding and lever setting, double roller escapement and adjusted to heat cold, isochronism and all positions. The Company guarantees the movement will vary less than six seconds in a calendar month" Note: A railroad watch is a watch that satisfies the requirements in effect at the time the watch was made. (railroad rules evolved and changed from year to year.) Prior to 1893, the definition of a railroad watch was optional with individual railroads. About 1893 the General Railroad Timepiece Standards Commission presented these new guidelines (below). After 1893, American watch manufacturers set out to meet these guidelines, later railroad lines used these standards as a guideline for NEW railway watches, but not ALL. Some Railroad Companies were vague about their regulations and some had none at all. Note: With over 500 American Railroad Companies and each one (no nation-wide rules) used similar but different rules and specifications. NOTE: 15 jewel watches were accepted by some Railroad Watch Inspectors as late as early 1900's. Be open faced, size 18 or 16, have a minimum of 17 jewels, adjusted to at least five positions, keep time accurately to within a grain or loss of only 30 seconds a week, adjusted to temperatures of 34 to 100 degrees Fahrenheit, have a double roller, steel escape wheel, lever set, micrometric regulator, winding stem at 12 o'clock, grade on back plate, use plain Arabic numbers printed bold and black on a white dial, and have bold black hands. NOTE: By about 1900 the above guidelines were used by many Railroad Companies Inspectors. The American Watch industry was compelled to produce just such an instrument which it did. The railroad watch was a phenomenal timekeeper and durable in long life and service. It had the most minute adjustments, no small feat because watch making was rendered far more difficult than clock making, due to the fact that a clock is always in one position and powered by a constant force-it's weights while watches must be accurate in several positions with a variable power source. After 1875-80 a railroad employee had to buy his own watch. After 1893 railroad pocket watch standards guidelines were adopted by some railroad lines for new watches. While each company had its individual standards guideline, many included the basic recommendations of the commission. One of the figures in developing the railroad watch standards was Webb C. Ball of Cleveland, Ohio, the general time inspector for over 125,000 miles of railroad in the U.S., Mexico, and Canada. Ball was authorized by railroad officials to help establish the timepiece inspection system. After Ball presented his guidelines, most American manufacturers se tout to meet those standards and a list of the different manufacturers producing watches of the grade that would pass inspection, was soon available. These standards changed from year to year. According to the regulations, if a watch fell behind or gained 30 seconds in 7 to 14 days, it must be sent in for adjustment or repair. Small cards were given to the engineers and conductors the railroad timekeepers and a complete record of the watch's performance was written in ink. All repairs and adjustments were conducted by experienced and approved watchmakers; inspections were conducted by authorized inspectors. Because this system was adopted the American watch manufacturers produced a superior railroad watch, the traveling public was assured of increased safety and indeed the number of railroad accidents occurring as a result of faulty timepieces was minimized. Prior to the 1890s, some railroad companies had already initiated standards and were issuing lists of those watches approved for railroad use. Included were the Waltham 18s, 1883 model, Crescent Street Grade, and the B. W. Raymond, 18s, both in open and hunter cases with lever or pendant set. By the mid 1890s hunter cases were being turned down as well as pendant set. Watches meeting approval then included Waltham, 18s, 1892 model; Elgin 7th model; and Hamilton, 17 jewel, open face, lever set. By 1900 the double roller, sapphire pallets and steel escape wheels with a minimum of five positions were required. The early Ball Watch Co. movements, made by Howard, used initials of railroad labor organizations such as "B. of L.E. Standard" and "B. of L.F. Standard". Ball also used the trademark "999" and "Official Railroad Standard". Some watches may turn up that are marked as "loaners". These were issued by the railroad inspectors when a watch had to be kept for repairs. By 1920 the 18 size watch had lost popularity with the railroad men and by 1950 most railroad companies were turning them down all together. In 1936 duty on Swiss watches were lowered by 50 percent, and by 1950 the Swiss imports had reached a level of five million a year. In 1969 the last American railroad pocket watch was sold by Hamilton Watch Co. a Grade 992B. NOTE: Railroad Standards, Railroad Approved and Railroad Grade terminology, as defined and used by Ashland. RAILROAD STANDARDS=A commission or board appointed by the railroad companies outlined a set of requirements to be accepted or approved by each railroad line. RAILROAD APPROVED=After 1875-80 a RR employee had to buy his own watch. A LIST of watches each railroad line would approve if purchased by their employee's. (this list changed through the years). RAILROAD GRADE=A watch made by manufactures to meet or exceed the railroad standards. Grades such as 992, Vanguard and B. W. Raymond, etc. *NOTE: Some GRADES exceeded the R.R. standards or requirements, such as watches with 23 jewels, diamond end stone, gold train, raised gold jewel settings, double sunk dial and the list goes on. Examples: Such as Veritas, Sangamo, 950 and Riverside Maximus and many others. NOTE: A railroad watch is a watch that satisfies the requirements in effect at the time the watch was made. There were no rules or guidelines used NATION-WIDE, watch railroad used their own rules and list of approved watches. RAILROAD GRADE WATCH ADJUSTMENTS The railroad watch, as well as other fine timepieces, had to compensate for several factors in order to be reliable and accurate at all times. These compensations, called adjustments, were for heat and cold, isochronism, and five to six different positions. These adjustments were perfected only after experimentation and a great deal of careful hand labor on each individual movement. All railroad grade watches were adjusted to a closer rate to compensate for heat and cold The compensation balance has screws in the rim of the balance wheel which can be regulated by the watchmaker. The movement was tested in an ice box and in an oven, and if it did not keep the same time in both temperature extremes, as well as under average conditions, the screws in the balance wheel was shifted or adjusted until accuracy was achieved. The isochronism adjustment mainted accuracy of the watch both when the mainspring was fully wound up and when it was nearly run down. This was achieved by selecting a hairspring or exact proportions to cause the blance wheel to give the same length of arc of rotation regardless of the amount of the mainspring that had been spent. Railroad watches were adjusted to be accurate whether they were laying on their face or back, or being carried on their edges with pendants up or down, or with the three up or the nine up These adjustments were accomplished by having the jewels, in which the balance pivots rest, of proper thickness in proportion to the diameter of the pivot and, at the same time, equal to the surface on the end of the pivot which rests on the cap jewel. To be fully adjusted for positions, the balance wheel and the pallet and escape wheel must be perfectly poised. Perfect poise is achieved when the pivots can be supported on two knife-edge surfaces, perfectly smooth and polished and when the wheel is placed in any edge, it will remain exactly as it is placed. If it is not perfectly poised, the heaviest part of the wheel will always turn to the point immediately under the line of support. NOTE: Railroad grade watches had a compensation balance made of brass and steel. Brass was used on the outside rim and steel on the inside. Brass is twice as sensitive to temperature changes and twice as thick as the steel balance (one-piece is welded to the steel balance wheel) and after finishing, the rim is cut at one end near the arm of the balance and at the same spot 180 across. In higher temperature, the dominant brass would "grow" longer but welded to the steel rim, it would curve inward, thus, in effect, placing the mass of the balance closer to the center of the balance wheel. This would cause the balance to go faster. However, the steel hairspring in rising temperature would also grow longer but more important would also lose some of its resilience. This would cause the watch to loose time. The balance, remember under the same condition, in effect became smaller and this action by the balance compensated for the loss of the hairsprings elasticity and lengthening. In cold temperatures, the opposite effect took place. This is why the balance is called a "compensation" balance. (It compensate for the temperature errors in the hairspring). NOTE: Movements marked Adjusted have a diversity or combination, of features. The best way to know for sure is to check the factory grade lists for specific adjustments. After about 1905 the movements were marked with the number of adjustments. The micrometric regulator or the patent regulator is a device used on all railroad grade and higher grade watches for the purpose of assisting in the finer manipulation of the regulator. It is arranged so that the regulator can be moved the shortest possible distance without fear of moving it too far. These is always a fine graduated index attached which makes it possible to determine just how much the regulator has been moved. The hairspring used on the so-called ordinary and medium-grade watches is known as the flat hairspring. The Breguet hairspring was an improvement over the flat hairspring and was used on railroad and high-grade watches. The inside coil of any hairspring is attached to a collet on the balance staff and the end of the outside coil of the hairspring is attached to a stud which is held firmly by a screw in the balance wheel bridge. Two small regulator pins are fastened to the regulator. These pins clasp the outer side of the hairspring a short distance from the hairspring stud. If the regulator index is moved toward the "S", the regulator pins will move allowing the hairspring to lengthen and the balance wheel to make a longer arc of rotation. This causes the watch to run slower because it requires a longer time for the wheel to perform the longer arc. When the regulator is moved toward the "F" these regulator pins are moved from the stud which shortens the hairspring and makes shorter arcs of the balance wheel, thus causing the movement run faster. Sometimes, after a heavy jolt, the coil next to the outside one will catch between these regulator pins and this will shorten the length of the hairspring just one round, causing a gaining rate of one hour per day. When this occurs, the hairspring can be easily released and will resume its former rate. The Brequet overcoil hairspring, which is used on railroad grade movements, prevented the hairspring from catching on the regulator pins and protected against any lateral or side motion of the balance wheel ensuring equal expansion of the outside coil. Railroad grade watches also used the paten or safety pinion which was developed to protect the train of hears from damage in the event of breakage of the mainspring. These pinions unscrewed in event of mainspring breakage, allowing the force to be harmlessly spent by the spinning barrel. Some earlier railroad grade watches had non-magnetic movements. This was achieved by the use of non-magnetic metals for the balance wheel hairspring, roller table and pallet. Two of the metals used were iridium and palladium, both very expensive. The Great Kipton Train Wreck  Oberlin Weekly News, April 23, 1891 According to the report in this newspaper, two trains came together fifty feet east of the Kipton depot. "A large piece of steam chest was thrown on the depot roof and rolled off". The article goes on to say that the concussion of the impact on the roof broke most of the depot windows.  The depot can be seen in both train wreck pictures. The local passenger train from the east was behind schedule and instead of waiting at Oberlin for the fast mail train to pass by from the west, went on to Kipton A freight train was sitting on the siding that the engineer had planned to use and going eight miles an hour by this time sought a second siding. The mail train came around the curve from the west going forty-five miles an hour. The engineer's view being blocked by the freight on the siding, he did not see the passenger train in time to slow down. Both engineers and a fireman were among those killed. Three postal clerks sorting mail also died. The accident occurred on April 18th and eight people died in the crash.

W.C.Ball was a Cleveland jeweler and as a direct

result of the collision he investigated railroad timekeeping,and finding

practices woefully deficient, instituted watch performance and inspection

standards in 1893. Subsequently he became Chief Time Inspector for many

railroads and had many American manufacturers produce a quality railroad

timekeeper: the Ball Railroad Watch.

RAILROAD WATCH DIALS

HAMILTON

HAMPDEN

E. HOWARD & CO.

PEORIA WATCH CO.

SETH THOMAS

UNITED STATES WATCH CO., MARION

Note: A railroad watch is a watch that

satisfies the requirements in effect at the time the watch was made. There

were no rules or guidelines used NATION-WIDE, each railroad used their own

rules and list of approved watches. |